Flexible Vehicle Platforms for Faster Development

Flexible Platform

In vehicle development, the concept and package design assumes a central role in the early phase, as this is where the technical foundations for the later products are laid. For a customer from China, Porsche Engineering used an existing vehicle architecture to verify the feasibility of a comprehensive platform concept with different body variants and drive systems in a relatively short time, and gathered valuable information for further development activities in the process.

When automobile manufacturers develop a new vehicle model, good advance planning is required. At the very outset of the development process, the technical concept and the package (definition of the vehicle geometry, including the ergonomics and usage conditions, as well as the definition and management of the different zones in the vehicle) must be defined so that the final developed vehicle will later correspond to the original ideas. Some projects require a different approach, however, for instance when an OEM has already started a vehicle development and later decides to launch further vehicles and drivetrain variants derived from the original concept.

An increasing number of such requests are coming from car manufacturers in China. “There are currently many new OEMs being founded there that have only been developing cars for a few years,” explains Humberto de Campos do Carmo, who as Senior Manager Vehicle Concepts and Package at Porsche Engineering has already implemented a wide range of different projects for customers worldwide. “These companies are therefore turning to us for conceptual platform development that takes into account all drivetrain variants and various model derivatives. They might wish, for example, to expand the existing vehicle concept into a platform by adding further body and drivetrain variants.”

Adaptable: Platforms must take into account the requirements of different drive systems and different model variants.

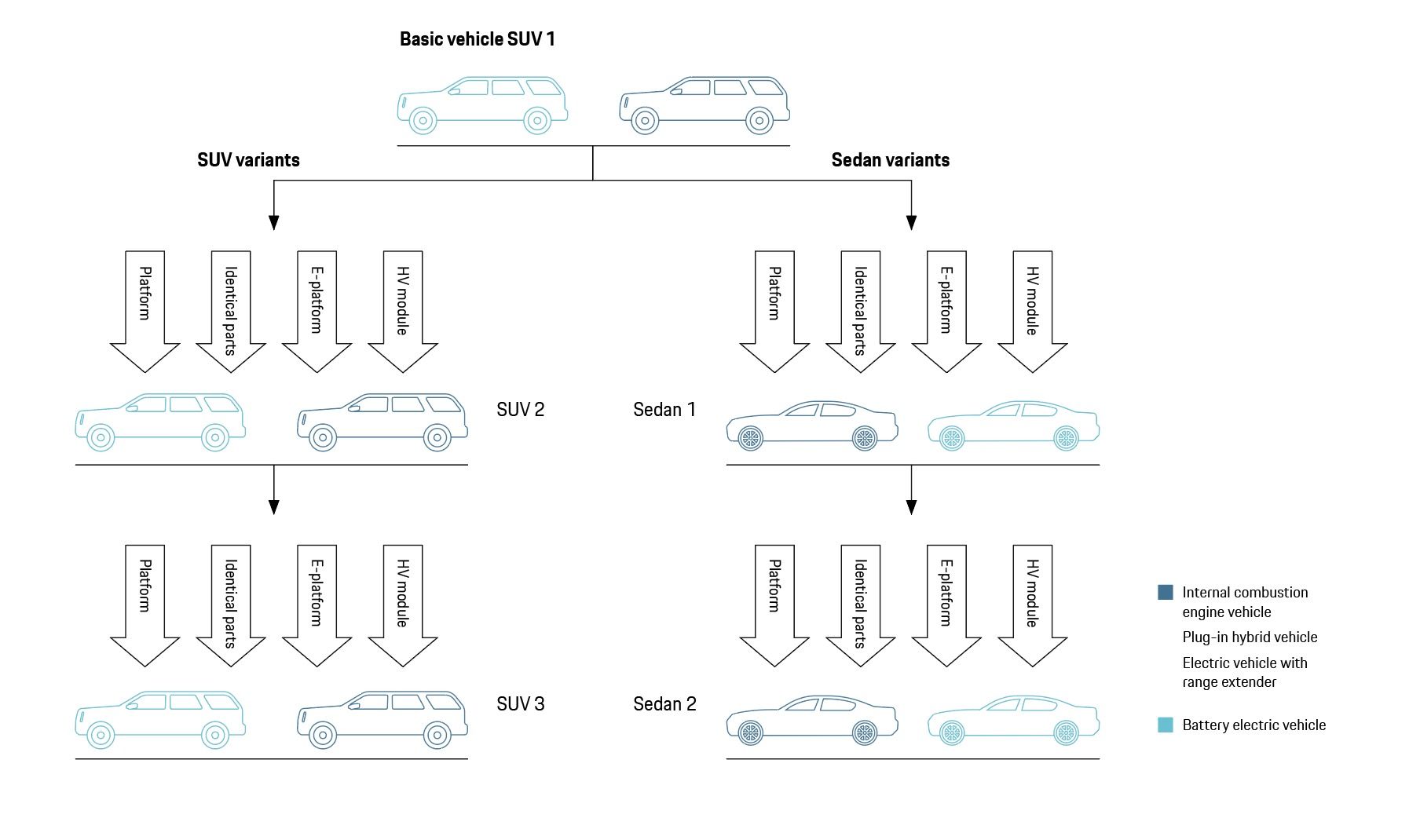

One recent example is a platform concept commissioned by a Chinese customer. The aim was to develop various derivatives based on an existing SUV model with an all-electric drive unit: on the one hand an additional sedan, and on the other hand drivetrain variants with internal combustion engines, an electric drive unit with range extender, and a hybrid system. If, as in this case, the concept development is to be based on an existing vehicle, the experts start with a precise analysis of the existing platform. “In each case, we focus on the most critical vehicle derivatives, such as the heaviest or most powerful variant—the worst-case scenario, so to speak,” explains de Campos do Carmo.

Studies indicated that the body structure of the front end was too soft for the heaviest derivative of the platform. “In order to improve crash safety, we proposed enlarging front longitudinal members,” reports de Campos do Carmo. “We also had to change the suspensions so that different ground clearances and heights could be achieved for SUV and sedan." Using tires with different diameters, springs of different stiffness, and special spacers on the axle carrier, the developers were able to adapt the vehicle height to the varying requirements without having to interfere with the basic axle design. The cooling system also had to be modified: the analysis showed that the heat exchanger was too small for the SUV version with a combustion engine. It was adapted to the new conditions in further vehicle development.

“We have experts from all vehicle sectors and we use the latest simulation and development tools.”

Humberto de Campos do Carmo

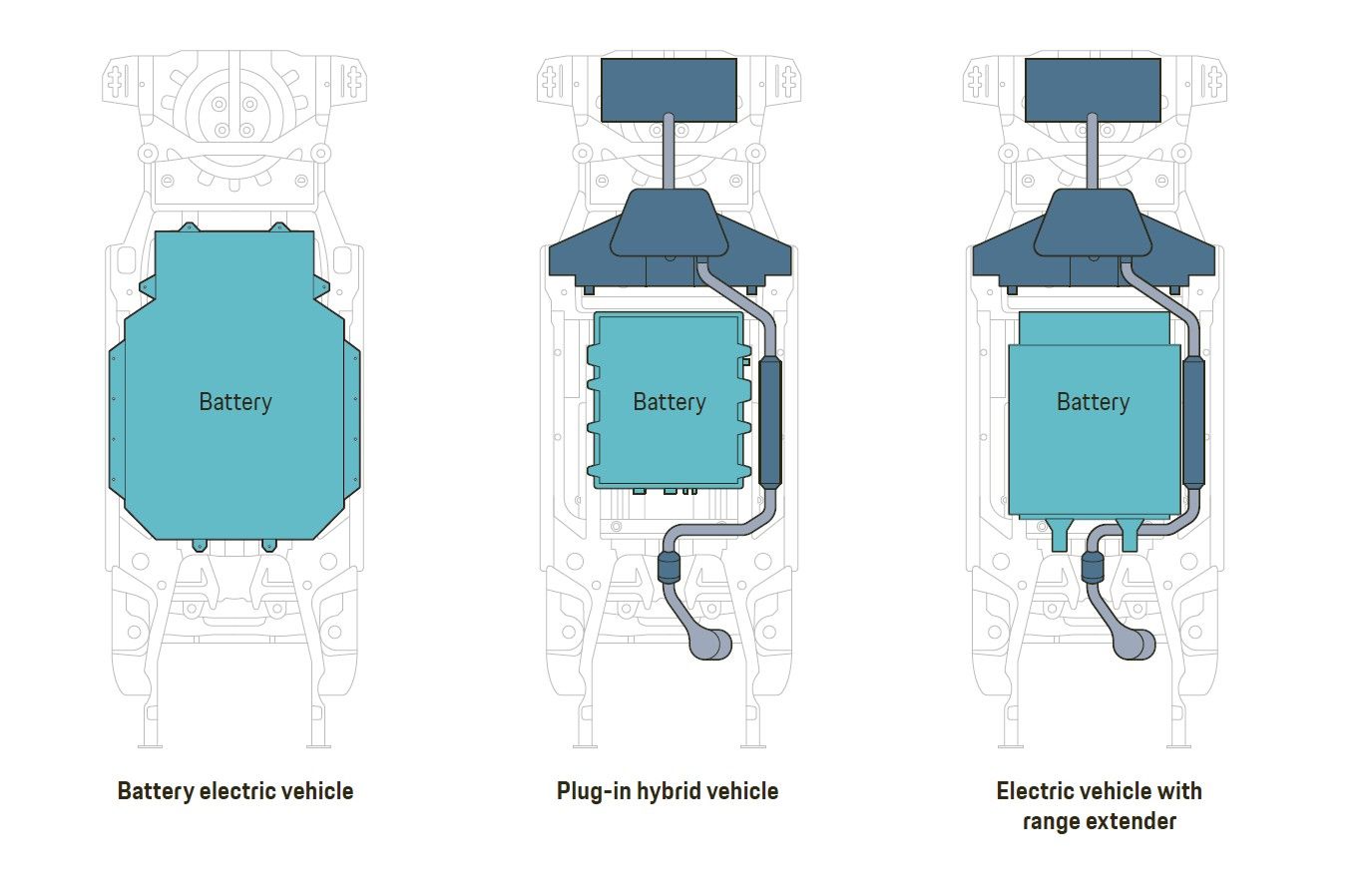

Senior Manager Vehicle Concepts and Package

One of the biggest challenges was the package of different sized batteries for the electric model variants. “Together with the customer, we developed the concept for an underbody structure that is identical for all vehicles,” says de Campos do Carmo. “In each case, different mounting points accommodate the different sized batteries of the electric variants, so we were able to avoid cost-intensive modifications in this area.” The battery of the purely electric vehicle fills the entire available package space; in the versions with the range extender and the hybrid drivetrain, the fuel tank for the combustion engine was placed behind the smaller battery pack.

Conceptual Platform Development

Starting from an existing SUV model with an all-electric drive unit, Porsche Engineering has developed several different variants: an additional sedan and drivetrain variants with internal combustion engines, an electric drive unit with range extender, and a hybrid system.

Core Elements of the Platform

If it becomes apparent during concept development that the effort required to change the existing platform is too high, the customer is faced with a choice: it can either skip its current project in favor of a platform-compliant solution or pursue both approaches in parallel. “From a cost perspective, the focus on the future-proof platform architecture would usually be best,” says de Campos do Carmo. “However, when a vehicle project is already very advanced, customers often decide to develop both concepts to market maturity at the same time and absorb the additional costs as a lesson learned.”

Ideally, a customer should therefore define the desired segments, drivetrain concepts and engine variants to be covered by a new platform in advance. This gives the engineers responsible for the concept and package basic conditions as well as maximum freedom and the opportunity to develop the vehicle platform in a targeted manner, while also allowing them to incorporate factors such as the automobile manufacturer's product and brand strategy into their considerations. The customer benefits from an efficient development process that leads to optimal results in a very short time.

Customers from China typically work on a very tight schedule, which is not comparable with the development cycles of European car manufacturers. “In the abovementioned project we had about six weeks from the requirements analysis to the finished result. To avoid communication problems in the coordination process, resident engineers from the customer supported us as a link to the development team in China,” says de Campos do Carmo. “This trusting and close cooperation was a decisive factor in successfully completing the project within the specified timeframe.”

Defining the concept and package of a new vehicle requires extensive experience at all levels of vehicle development and the development methodology chain. “We have technical experts from all vehicle sectors, and we use the latest simulation and development tools,” says de Campos do Carmo. “And then, of course, there is the high degree of flexibility and customer focus with which we handle development projects, which is also appreciated by our partners in China.”

Step-by-Step Development

The optimal accommodation for passengers: This is the most important goal of every vehicle concept. The first step is the ergonomics concept on the basis of anthropometry (the science of the human body and skeletal characteristics). The dimension concept describes the geometric values and interrelationships; it also takes into account legal requirements and the geometry of components. Finally, the package concept guarantees that in the end everything is in the right place. The idea of the package concept is to bring the goals of the departments into line with their sometimes contradictory requirements.

Common Underbody Structure

Different mounting points of the common underbody structure accommodate the differently sized batteries of the electric variants. The battery of the all-electric vehicle fills the entire available package. In the versions with the range extender and hybrid drivetrain, the fuel tank for the combustion engine is located behind the somewhat smaller battery pack.

Package of High-Voltage Batteries

China is currently experiencing a real hybrid and electric vehicle boom, which is leading to the development of a large number of new vehicle concepts. “Many of the car manufacturers are start-up companies to whom we can provide technical support in integrating the high-voltage battery into the vehicle,” says Stefan Bender, Lead Engineer Battery Package at Porsche Engineering.

In general, the high-voltage battery is the largest and heaviest individual module that has to be accommodated in the vehicle as part of the concept and package development process. The requirements for crash safety, the vehicle’s center of gravity position, which is important for driving dynamics, the high-voltage wiring of the complete electrical system, and the thermal management of the energy storage system reduce the developers’ leeway in the placement of the battery system. “Since with high-voltage batteries, literally every millimeter counts, a precise definition of the technical requirements is the basic prerequisite for package development,” says Bender.

Single Cell Module: The high-voltage battery has a major impact on crash safety and driving dynamics. Its integration is therefore a special challenge.

Many smaller companies lack this analysis. “The result of this is quite often that, together with the customer, we create a development process tailored to the customer's needs in parallel with the actual battery package project,” says Bender. As an example, he cites a customer who wanted to integrate an oversized battery into his vehicle. “Together with the customer, we first determined what performance the vehicle, and thus the battery, had to provide.”

In order to be able to meet all the specifications in terms of their mutual interactions, the integration of the battery into the vehicle must be initiated as early as possible in the development process. This applies both to all-electric vehicles and hybrid models based on a conventional vehicle platform designed for combustion engines, where there is no excess construction space for the battery. The aim is always to design the battery module as compactly as possible during the development phase in order to leave plenty of space for placement, and then to accommodate it in the vehicle as required. “If a customer gives us the cell module for the vehicle project, we integrate it in such a way that it meets all requirements in the best possible way,” says Bender. “However, overall system solutions in which we can develop the battery unit individually and tailor it to the package are preferable.”

“If a customer gives us the cell module for the vehicle project, we integrate it in such a way that it meets all requirements in the best possible way.”

Stefan Bender

Lead Engineer Battery Package

Here, Porsche Engineering can draw on expertise gained over decades in the development and optimization of the electrical, mechanical and thermodynamic properties of batteries. For example, the experts use calculation models that are created and validated in-house—for example for the “heart” of the energy storage system, the battery cell. In addition to the simulation tools, test benches are also available to them.

“In the concept and package of a traction battery, we consider all the details of the vehicle. For example, a sports car, unlike a city car, can be expected to have high instantaneous currents,” explains Bender. “We adjust the connection of the individual cells within the battery pack to this, for example, so that the contact resistances and the resulting heat generation over several acceleration processes in quick succession do not increase too much and the engine power does not have to be reduced for component protection reasons.”

In Brief

Ideally, concept development occurs at the very beginning of a project. But a platform concept for additional drivetrain and model derivatives can also be derived from an existing vehicle. In the case of a Chinese customer, Porsche Engineering has succeeded in doing this by modifying the chassis, cooling system, and underbody, among other things.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2020.

Text: Richard Backhaus

Contributors: Humberto de Campos do Carmo, Stefan Bender

Illustrations: Florian Müller

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de