How Automotive Tech Improves Motorcycles, Boats, and Tools

Transfer of Innovative Efficiency Technologies

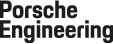

Gasoline engines are not only found in millions of cars—they also power motorcycles, mopeds, boats, small machines, and stationary work equipment. In all of these areas, laws are becoming stricter, and the demands of customers are rising as well. Porsche Engineering can transfer the technologies from the automobile to these non-automotive fields.

Gasoline engines can look back on an astounding development history: First driven by the desire for greater power and convenience, and later by strict consumption and emissions regulations, today they are technologically sophisticated systems highly optimized for their purpose. Many new technologies have played a role, including direct fuel injection, exhaust aftertreatment, downsizing, and hybridization. And although the long-term trend is in the direction of electric vehicles, gasoline engines will probably still power roughly 70 percent of all passenger vehicles in 2050, albeit mostly as hybrid variants in combination with an electric motor.

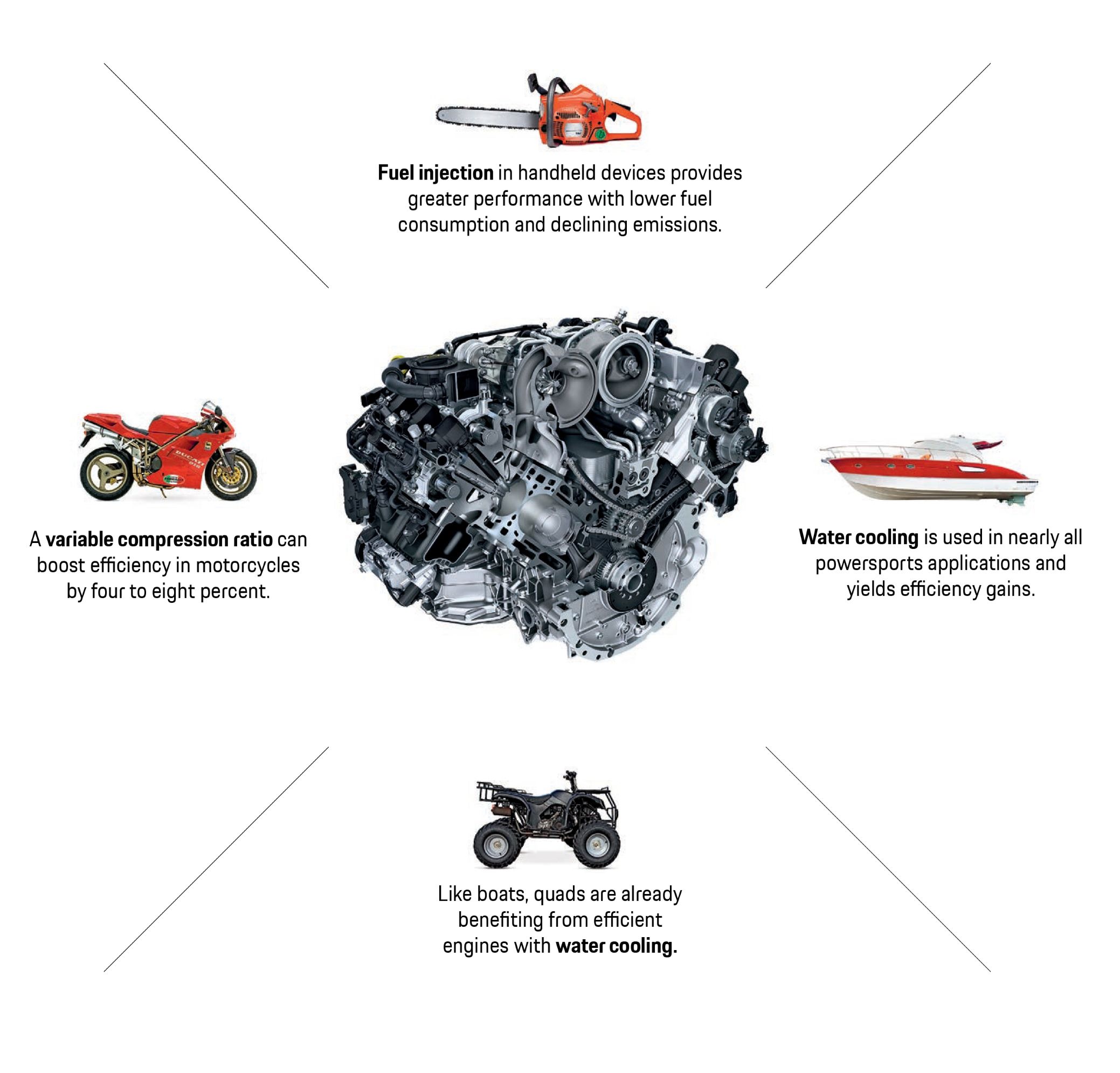

Motorcycles, mopeds, and boats will also continue to use gasoline engines for a long time to come. However, legal requirements will become stricter and customers more demanding in this area as well. “For motorcycles, EU emissions thresholds have also been drastically reduced,” reports Klaus Fuoss, Director of the Engine Department at Porsche Engineering. “By 2020, carbon monoxide emissions cannot exceed 1,000 and emissions of hydrocarbons will be limited to 100 milligrams per kilometer, which is equivalent to the passenger vehicle limits in place in 2005.” As for nitrogen oxides, only 60 milligrams per kilometer will be allowed, which was the limit for passenger vehicles in 2009.

A similar development has taken place for small devices (handheld and non-handheld) such as power saws and lawn mowers. Depending on the displacement of the motor, handheld devices may only emit a maximum of 50 to 72 grams of hydrocarbons and nitrogen oxides respectively (combined per kilowatt-hour of work) under US and EU regulations. For non-handheld devices, between eight and ten grams per kilowatt-hour are allowed.

Beyond legislation, customers are also becoming more demanding, for instance with high-performance motorcycles. “Here the demand is for strong performance at high engine speeds combined with better driving characteristics at low engine speeds,” says Fuoss. In emerging economies, by contrast, millions of people are dependent on mopeds that are robust and efficient–and that can comply with ever-stricter emissions limits with inexpensive technology.

With work equipment, users are demanding better protection: The German trade associations, for example, specify a threshold of 35 milligrams of carbon monoxide per cubic meter of breathing air. The odorless gas can collect in mines and other spaces and has a toxic effect. The hydrocarbons in exhaust gas are also problematic: they not only give off an unpleasant odor, but also contain carcinogenic benzene rings.

So the gasoline engine has to become cleaner—and not just in cars. However, many companies in the non-automotive sector lack the big development budgets of the automobile manufacturers. “There is therefore a need for the intelligent transfer of mature technologies from the car to other applications,” says Fuoss. “The motorcycle manufacturers are the furthest along here, with the law lagging six to eight years behind the regulations for passenger vehicles.” Many elements from the car are therefore already in high-priced motorcycles, such as mechanical charging with superchargers.

Familiar with All Technologies

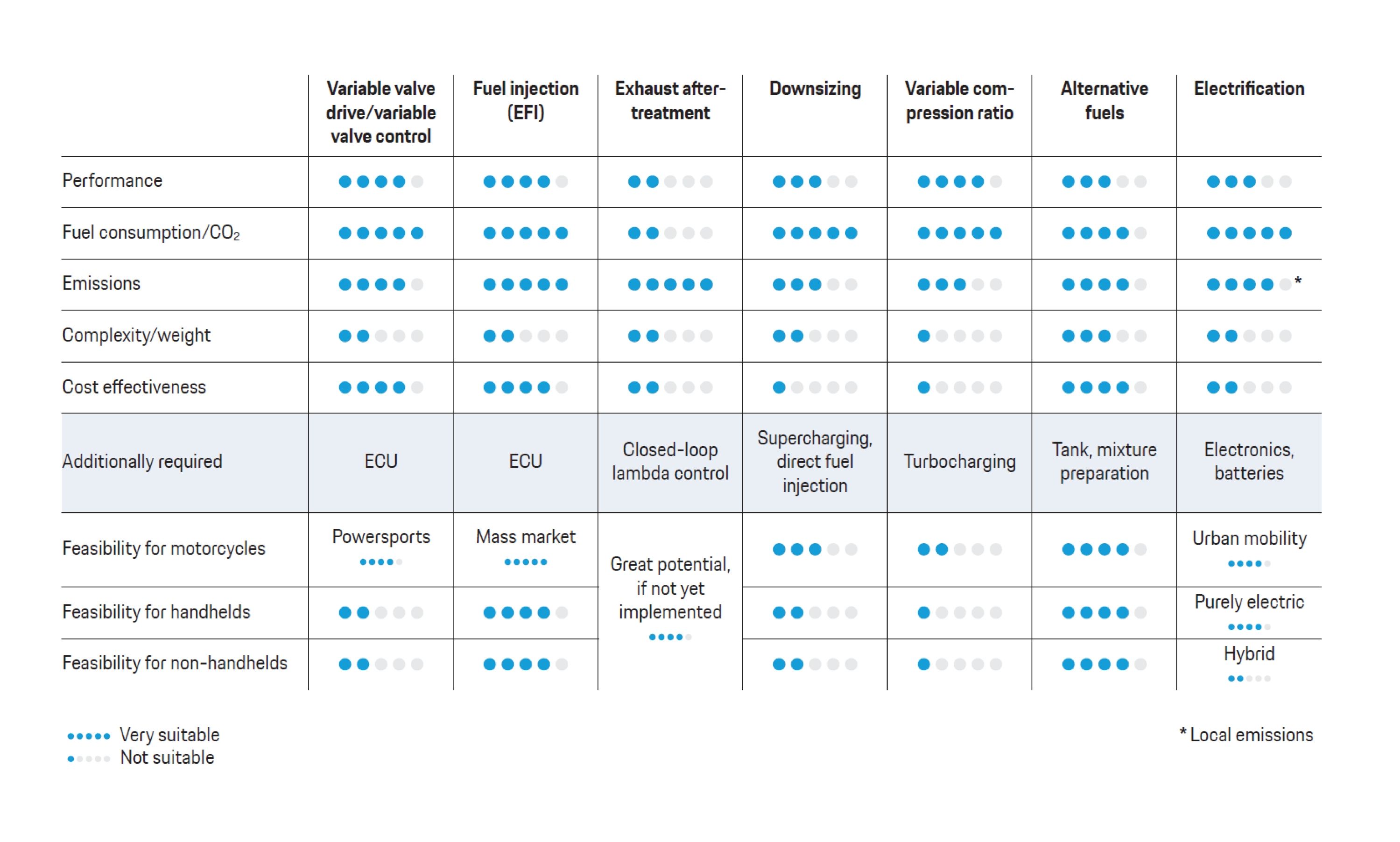

Porsche Engineering is well versed in all efficiency and environmental protection technologies in the gasoline engine area and can support companies in the non-automotive sector with the transfer of such technologies to their products—always bearing in mind specific requirements such as low costs or the lowest possible weight. However, not every technology is suitable for every product. “In each case a precise analysis must ascertain whether the defined objectives can be achieved in an economically viable manner,” says Fuoss. To provide better orientation, the experts from Porsche Engineering have examined technologies in terms of their use in motorcycles and handheld and non-handheld devices: alternative fuels, fuel injection, exhaust aftertreatment, variable valve drives, variable compression, down- and rightsizing, electrification, and water cooling.

The fastest reductions in carbon dioxide and other emissions could be achieved through alternative fuels such as methane as a gasoline substitute: Due to the favorable ratio of hydrogen to carbon atoms, gasoline engines would emit roughly 25% less CO2. Renewably generated CH4—for instance produced by way of electrolysis from renewable electricity and subsequent methanization—would actually be entirely climate-neutral. What's more, there are fewer toxic components in the alternative fuel. “From a technical standpoint, it absolutely makes sense to replace gasoline with such alternatives,” says Fuoss. “Moreover, only minor modifications to the engines are required.”

Fuel injection is also one of the promising technologies for non-automotive applications—even in power saws. Through more precise timing and more accurate mixture preparation, the technology offers more performance at lower fuel consumption and emissions levels. Above all, the emissions of hydrocarbons could be reduced. What has already proven successful in motorcycles and jet boats could soon find the way into handheld and non-handheld devices. “The development expense is reasonable, and the additional weight of 100 to 200 grams is acceptable even for handheld devices,” says Fuoss. “When and how quickly fuel injection comes to this area will, however, depend crucially on future emissions limits.”

Its use would be particularly useful in combination with exhaust aftertreatment. Three-way catalytic converters are already in use in motorcycles today, reducing their hydrocarbon, carbon monoxide and nitrogen oxide emissions. In principle, handheld devices and stationary work machines could be made more environmentally friendly as well. It would carry a price, however: Due to restriction of the exhaust gas temperature, performance is diminished, and fuel consumption actually rises. “And due to the expensive precious metals in the catalytic converters, costs rise as well,” explains Fuoss. “Technically there are no obstacles to exhaust gas aftertreatment in handheld and non-handheld devices—but it will only be introduced if mandated by law.”

Variable valve drives are an interesting technology for powerful motorcycles. They enable greater flexibility in the gas cycle, which leads to higher performance, lower emissions, and lower fuel consumption. Due to high costs, however, variable valve drives are not an option for handheld and non-handheld devices. A similar picture emerges for motors with a variable compression ratio. “The efficiency gains of four to eight percent could certainly be interesting for motorcycles in the future,” says Fuoss. “There is also the possibility of lowering emissions significantly in conjunction with the Miller method and supercharging. For handheld and non-handheld devices, however, this technology is also too complex and too expensive. As with cars, downsizing and rightsizing can also lead to reduced fuel consumption in motorcycles.

60

milligrams

Low Range for Electric Drivetrains

Motorcycles and work equipment can be made locally totally emission-free through electric drive systems. There are still many unanswered questions here, however, such as operating duration. “Electrically powered motorcycles provide outstanding acceleration, but still offer limited range—which is bad for long tours,” explains Fuoss. “So at the moment it is difficult to say whether they will be successful.” And those who wish to power handheld and non-handheld devices electrically may have to secure adequate operating times through the use of multiple batteries—which drives up costs.

Water cooling also yields efficiency gains in combustion engines and is already used in nearly all powersports applications (including motorcycles, boats, and quads). Small devices use simplified water cooling systems in some cases, but they have not gained traction due to cost and weight drawbacks.

So in the view of the experts from Porsche Engineering, all indications are that gasoline engines will continue to be used for some time to come even beyond automotive applications. It is therefore important to transfer innovative and economically viable efficiency technologies from the automotive sector to new applications.

Emissions Regulations are Getting Stricter

As in the automotive sector, motorcycles, handheld, and non-handheld devices are also subject to increasingly stringent limits for carbon monoxide, hydrocarbons, and nitrogen oxides. Compliance with those limits requires the transfer of efficiency technologies from the automotive sector.

Application-Specific Analysis Required

Not every efficiency technology from the automotive sector is suitable for transfer to other applications. Factors such as cost, weight, and dimensions can be decisive.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2019.

Text: Christian Buck

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de