Rimac: From Garage Project to Porsche Tech Partner

Electrified

Mate Rimac builds electrically powered supercars in Croatia. OEMs know him as a supplier of reliable, high-performance battery systems. Porsche, too, holds shares in Rimac Automobili and works on battery technology together with the company.

It was clear early on where his life would take him. “I’ve been a car nut for forever, from before I could even walk or talk,” Mate Rimac remembers. “No idea where I get it from. It’s nothing to do with my family, that’s for sure.” Wherever he caught horsepower craze, cars have been at the heart of almost everything throughout the thirty-two years since he was born. Mate Rimac managed to make his passion his profession: Since 2009, he’s been head of Rimac Automobili, the only car manufacturer in his home country of Croatia. The company is based in Sveta Nedelja near the country’s capital, Zagreb. Porsche joined as shareholder in 2018.

High-Flier: Company founder Mate Rimac in front of an autoclave his company uses to manufacture composite fiber components.

Crazy About Cars: As a kid, Mate Rimac caught horsepower craze. Today, he’s head of Rimac Automobili, the only car manufacturer in his home country of Croatia.

Rimac’s specialty are electrically driven supercars, two of which we can see on display in the company’s entry hall. They’re both a Concept_One, the company’s first model that saw only eight units produced. More than 1,200 hp, 1,600 Nm of torque, 0 to 100 km/h in 2.5 seconds. Top speed 355 km/h. At the 2018 Geneva Motor Show, Rimac Automobili presented the successor model, the C_Two. Its four electric motors—one for each wheel—treat the road to more than 1,900 hp and 2,300 Nm. On racing tires, it makes it from 0 to 100 km/h in under two seconds. Electronic fuel cutoff stops the speedometer needle at 412 km/h. The company plans to build 150 units of the electric sportscar. They’ll come in at two million euros apiece.

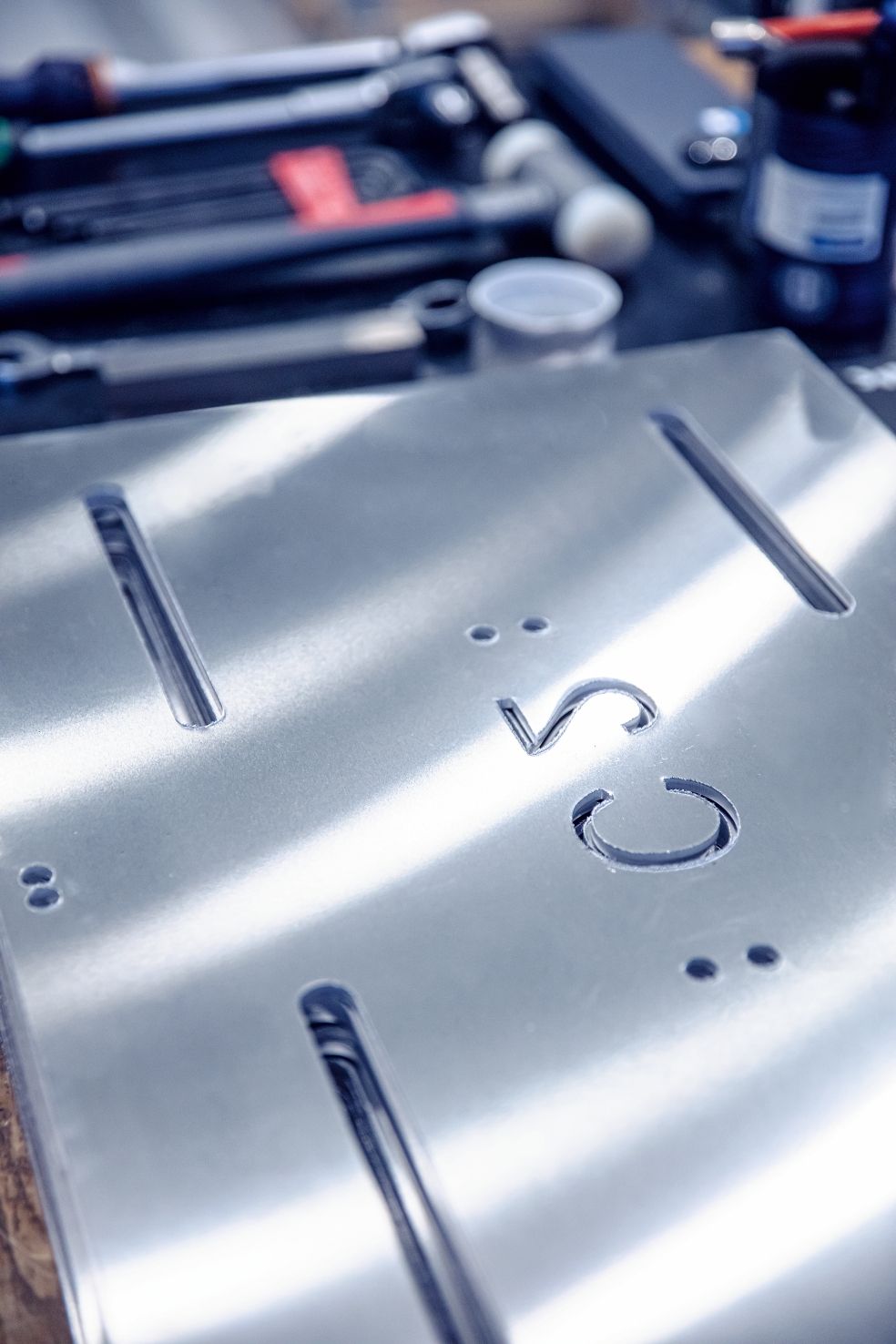

The C_Two prototype models four and five are in the workshop, Rimac technicians tinkering away at their electronics. A black 198-kilogram carbon monocoque lies ready for a third prototype in the corridor, only a couple steps away from the two large autoclaves. These cylindrical ovens are where the company produces all their composite fiber components at temperatures of up to 350 °C. A short way across the corridor, Rimac workers are piling CFC mats into molds layer-by-layer, lifting each of them by hand. Around 2,000 hours of work go into each car.

Building Success with Your Own Hands

Rimac’s story of success also begins with a whole lot of hands-on work. At the age of 18, our young horsepower fan bought himself a BMW 3-series. The car rolled out of the factory in 1984, making it four years older than Mate Rimac. The aging engine blew up on him in only his second drift race. This gave the passionate electronics tinkerer the idea to try out an electric powertrain. He presented at the races again with an electric motor taken from a forklift and some second-hand batteries, and was met with ridicule at first. “Can I charge my cell from your car?” was only one of the mocking questions asked back then.

But Rimac persevered and showed them all in the end. Though it took several conversions, his electric BMW eventually beat the fossil-fueled competitors, his vintage car even breaking all of five FIA acceleration records in 2011. Not surprisingly: thanks to technical improvements, the car was by now putting out 600 hp at 900 Nm of torque, making it from 0 to 100 km/h in 3.3 seconds. Its extreme performance—and because it was painted green—earned the BMW the nickname “Green Monster.” We can’t find it on a tour of the company grounds, however. “The BMW needs to be restored because a friend of mine drove it into a wall a couple years ago, wrecking it pretty badly,” Rimac says.

Where Electric Supercars Are Born: Rimac Automobili staff are currently testing the prototypes for the new model C_Two. The company produces all components in-house, most of them painstakingly by hand. In the showroom, visitors get to see the racecars and e-bikes by Rimac’s sister brand Greyp.

Another pretty beat-up exhibit shown in a display case on the grounds is a battery system. It was stuck in a fire for two minutes as part of a test to prove that it would withstand even such extremes. This kind of reliable, high-performance electric energy store, along with the matching electronics, are Rimac Automobili’s specialty. These, too, are designed and produced in-house, at a secluded site only a few kilometers away from the HQ in Sveta Nedelja. The site is well shielded from prying eyes. By design: Rimac produces components for customers here, too.

“We generate 80 percent of our turnover through component sales,” Rimac tells us. “Our own cars make ideal promotion platforms and are a perfect test bed for us to go crazy with new tech.” Becoming a supplier was necessity rather than choice. After its founding, the startup business faced financial collapse all the time. “They shut off our power and I didn’t know how I was going to pay my people’s wages,” Rimac remembers. “I had to grow up early back then.” Just before using up his last reserves in 2011, he drove to the International Motor Show Germany (IAA) to present his first car—and brought home his first work order as a supplier. A customer wanted to build an electric car and asked Rimac to help. “That was how I survived and how I managed to pay the six people I was employing back then, because it was instant sales.” From there, the projects just kept rolling in, more and more of them, including entire powertrain systems and prototypes for suppliers and tech firms.

Sveta Nedelja is a small town with a population of around 18,000 located roughly 17 kilometers outside of Croatia’s capital Zagreb.

But for Mate Rimac, moving into component supply meant more than just escaping pressing financial difficulties. “Without gaining that customer experience we’d likely have taken it in the wrong direction, burned all our investors’ money and wound up dead in the water. Instead, we built a team, built expertise, and made a name for ourselves as a reliable tech company.” And so, Rimac pulled off what so many have failed to do: he founded a new automobile manufacturer, one that today employs around 650 people.

His expertise in electric drives attracted not only customers but also brought investors to Croatia. Among them Porsche, who continued investing after their initial buy-in in 2018, now holding 15.5 percent of shares. “We understood early on that Porsche and Rimac could learn a lot from each other,” says Lutz Meschke, Deputy Chairman & Member of the Executive Board—Finance and IT at Porsche AG. “We believe in Mate Rimac and his company, that’s why we’ve increased our share now. We’re also expanding our collaboration in the field of battery technology.”

650

staff

15,5

%

of Rimac shares

Battery-powered electric drive systems are the future, of that Mate Rimac is sure: “Fuel cells can’t cut it; producing hydrogen requires far too much energy. They’ll offer benefits in some niche applications, perhaps, maybe for buses or trucks.” The new drive technology does not pose a threat to established OEMs and suppliers, he believes: “Used to be you installed combustion engines in cars. In future, you’ll be installing electric motors. There’s not much difference, essentially.”

Changes in consumer behavior will impact the industry far more severely. “Young people today don’t see cars as a mark of status anymore. To them, it’s a means to an end. And why should they spend months learning how to drive if self-driving vehicles will soon be a far safer and more efficient option? Today, accidents still kill more than a million people worldwide and cause massive economic damage—because, among other things, humans only feature ‘two poor cameras.’ Self-driving cars have better cameras and, on top of that, also have radar and lidar sensors. This will make computers the better drivers.”

In Tomorrow’s Mobility, Personal Cars Are a Collector’s Piece

That’s why Rimac believes most people in future will travel in self-driving, primarily electrically powered cars provided by carsharing or ride-hailing services. “Of course there’ll still be privately owned cars, but they’ll be like horses are today: a collector’s piece. Cars are tomorrow’s race horses.” The automotive industry’s customers in this future of mobility would then no longer be private owners but instead fleet operators with very precise expectations of their vehicles—built from the vast amount of data gained from day-to-day operations. This will include data on regular usage and customer behavior during trips, in turn making it possible to define range or equipment- feature requirements.

“We know how to cram a lot of performance into a tight space.”

Mate Rimac

Successful Businessman: Few only have managed to set up a new automobile manufacturer in recent decades. Mate Rimac is one of them—thanks to his experience as a component supplier. His own products, like the C_Two, act as promotions platforms.

Rimac considers his company well equipped to meet the future. “We know how to cram a lot of performance into a tight space. This is why everyone who wants a high-performance electric vehicle or hybrid comes knocking on our door. But we’re also capable of delivering fun electric driving to a mass market.” The engineers in Croatia are looking into self-driving cars, too, albeit for a more niche application: The modified C_Two will feature a computer-aided “Driver Coach” programmed to help the owner become a better driver at speeds of 300 km/h on a race track. “Bringing driving excitement to self-driving cars,” Mate Rimac calls it.

Rimac: Milestones in a Success Story

In Brief

Rimac Automobili is a firmly established manufacturer of electrically powered supercars and component supplier for high-performance battery systems to OEMs worldwide. Company founder Mate Rimac broke world records with a BMW he converted to electric drive. He believes most people will travel in self-driving cars in the future.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2020.

Text: Christian Buck

Photos: Alexander Babic

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de