)

Where Innovation Meets the Chinese Market

Highly Sought Expertise

In Anting near Shanghai, around 75 Porsche Engineering staff work for Chinese car manufacturers and customers from the VW Group. The site has cutting-edge test facilities and investigates the latest trends in the automotive industry as well as automated driving and e-mobility.

Not far from the world-famous Formula 1 race track Shanghai International Circuit, we find the town of Anting. Anting was an early bird in becoming a key location for the Chinese automotive industry. Shanghai Automotive Industry Corporation (SAIC) was founded there in 1984, with the joint venture SAIC-VW following in 1988. Today, start-ups like Nio and suppliers like Schaeffler, ZF, and Brose maintain sites here, too. Almost everything else in town is also all about cars. In 2007, an automobile museum opened in Anting, and right next to it we find the Porsche Experience Center. So it makes sense that Porsche Engineering chose Anting to set up its Chinese base.

The company has pursued engineering projects together with its local customers here since 2015. Key fields of research are suspension systems, high-power charging, and software development. Porsche Engineering’s Chinese operations have a fair history: the engineers have been active here for more than 25 years—opening a branch here was the logical thing to do. “Customer projects have always been part and parcel of Porsche,” says Kurt Schwaiger, head of the Shanghai branch. “We’re simply continuing the history.” Besides Chinese OEMs, the key accounts also include companies from the VW Group.

Autocity: In Anting, almost everything is about cars. Porsche Engineering maintains a site here tailored to the local customers’ specific requirements and with access to one of China’s best talent pools.

Better Response to Customer Requirements

Kurt Schwaiger plans to use the Anting site to respond more rapidly to customer requirements. For one thing, there’s a time difference between China and Germany of six or seven hours—depending on the season. Always a stumbling block in terms of quick project turnaround. Then there also used to be language barriers. Opening a local site eliminated those. Today, Kurt Schwaiger and his team can support Chinese customers in developing vehicles, while filling in western customers on valuable details concerning the Chinese market.

With the Chinese market undergoing major change, Porsche Engineering’s expertise is highly sought lately. The times when China was “the world’s workshop” have long gone. The country is advancing towards a high-tech economy with a large, well-educated, and affluent middle class. The customers have long been just as demanding here as they are in the traditional markets. And the government has ambitious plans, too: China wants the intelligent and connected vehicle—ICV for short—to be a common sight on its roads by 2025 at the latest. The aim is to have all vehicles communicate in real time and to share data, for example on congested traffic. On top of that, China wants 15 percent of all vehicles in the country to be highly automated and ten percent to be driving entirely by themselves by no later than 2030. This gives the Chinese market tremendous influence on the future of the motor car.

25

+

years

2015

100

+

staff

Porsche Engineering in Shanghai deals with more or less every aspect of vehicle design. “It all started off with chassis design,” Kurt Schwaiger says. “We made a name for ourselves with that here.” Today, this has become entire suspension systems based on highly advanced electronics: all-wheel steering, stabilizers, four-wheel drive, air suspension. “The past two years have seen customer interest in electronic suspension systems rise significantly,” Kurt Schwaiger relates.

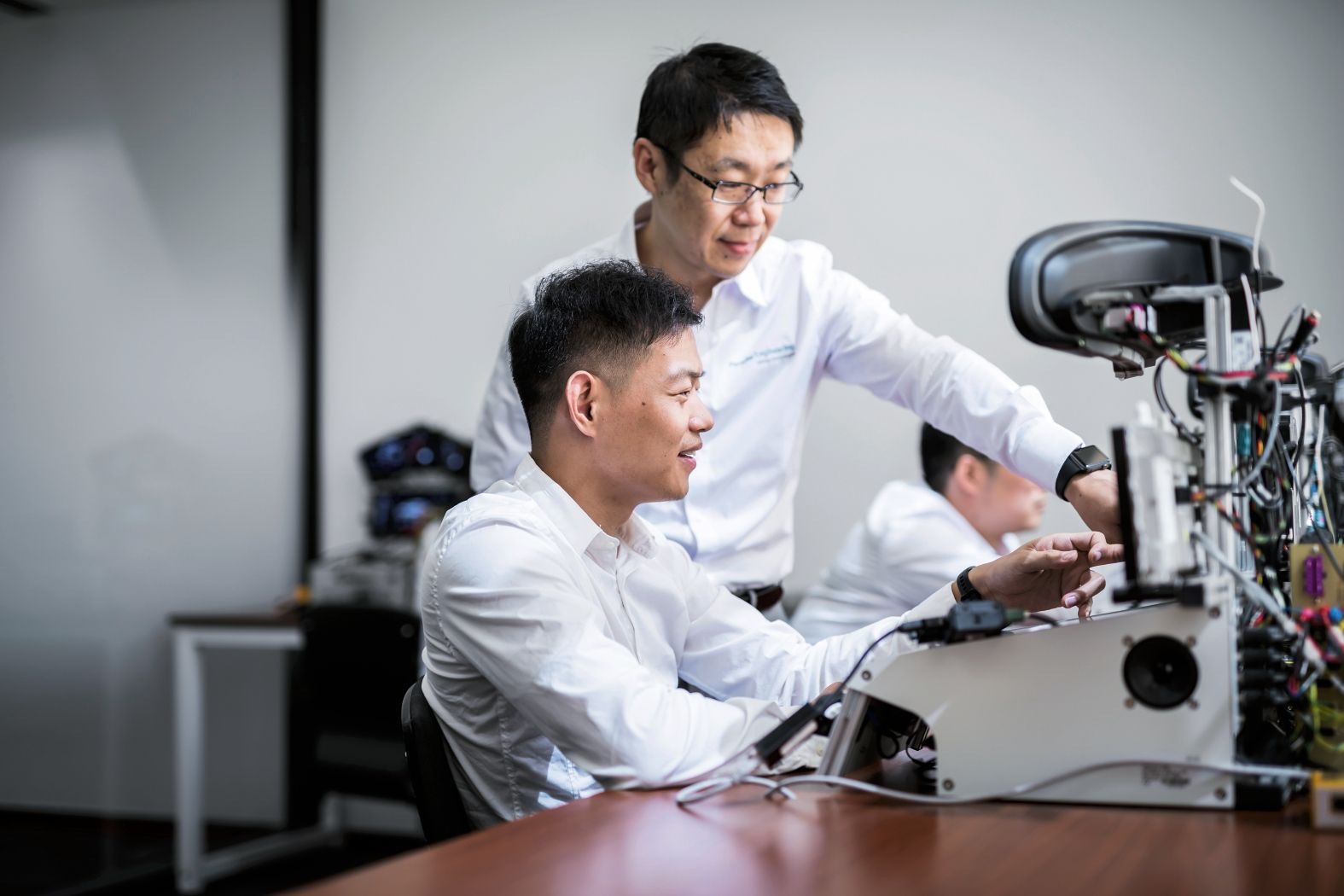

And then there’s the electrical engineering and electronics division (E/E), which is the one that deals with all of the smart control units in a vehicle. The tech specialists at Porsche Engineering in Shanghai always start by developing the software to match their customer’s specifications, and in the next step test it on HiL (hardware-in-the-loop) test rigs. The test rigs lead the control units to act just as they would if they were in a real vehicle, enabling trial runs long before any prototypes are available. While before, all tests ran in Germany, Anting now has the necessary equipment on site. “We save so much time now that we can run the important tests right here and right away,” says Naikai Du, who is also responsible for HiL test rig development in Anting.

Chassis Systems for China: Staff fine-tuning and checking the chassis components.

High-Power Charging: Testing a battery and battery management system for electric vehicles.

Check: Reviewing designs for suspension components.

High-power charging for electric vehicles is another major topic in China, where a huge market for electric cars is emerging. Porsche Engineering developed a special charging station that delivers up to 350 kW of charging power to recharge a Porsche Taycan in mere minutes. The major markets, however, all observe different standards. China is subject to the national GB/T standard (GuoBiao), which means that the charging station needs to be adjusted to comply with the Chinese market’s specifications. “We and a local enterprise are acting development partner for this. All Porsche dealers in China will be supplied this charging station,” Kurt Schwaiger says.

Porsche Engineering’s work in Anting is moving steadily more and more into software development. This is due to some extent to the smart chassis systems, but overall is owed to the new electronic driver assistance systems, which lead up to the self-driving cars of the future. These assistance systems require even more than others to be designed on site in China. “Chinese traffic is different to traffic in Europe or the USA. The people have a different way of driving,” the expert, Ben Wang, explains. “For instance, the relative number of beginner drivers is much higher in China. Some of the traffic signs are different, too, and automatic parking needs to take into account that underground parking lots in China are designed differently.” Ben Wang hails from the neighboring province of Jiangsu. He joined Porsche Engineering two years ago. He considers his job both a challenge and an inspiration: “We’re always needing to adapt to new customer requirements. The fields of traffic and traffic control, for example, are massively in flux.”

Seamlessly Integrated Car and Phone

Testing and validation are also part of the Shanghai branch’s portfolio. Here, infotainment systems and their interconnectivity are a key field of operations. “Chinese drivers consider these things really important,” says Kurt Schwaiger. Indeed, smartphones feature in every walk of life here, perhaps more so than anywhere else in the world. Nowadays, almost every day-to-day activity is resolved, optimized, and measured using a mobile phone. With WeChat, for example: on the face of it, the app is the Chinese version of WhatsApp. But it also acts like Instagram, Facebook, Twitter, and—most significantly—as a credit card. Almost all payment transactions in China these days use WeChat Pay, or its competitor service Alipay. “So Chinese drivers all assume there’s a seamless integration between car and smartphone,” Kurt Schwaiger says.

“Chinese traffic is different to traffic in Europe or the USA. People have a different way of driving.”

Ben Wang

Manager Software Development

Network integration goes further yet, pursuing prevention of congestion and immediate detection of accidents. “Plug-in hybrids and fully electric vehicles send related data to the national data center via a corporate server,” Estha Li explains. She comes from Beijing and has been on board with Porsche Engineering since 2017. “Our server lets us share data specifically and as needed, which lets us realize all kinds of support for drivers. The corresponding functions have to be developed here in China, indeed they couldn’t be developed elsewhere.”

Kurt Schwaiger, the branch manager, has lived in Shanghai for the past ten years. When he took on his job in Anting in 2015, the Shanghai branch employed a staff of eight. Today, 75 people work here, and staff will be increased to over 100 by year’s end. At the same time, the business premises will grow from 1,500 to 2,100 square meters. Geographically, the premises divide into two locations: the larger of the two lies in the Autocity Innovation Park in Anting. In the months ahead, a second building will be rented to allow for expansion of the team. The first floor will feature a workshop accessible to customers. The branch’s second location is in Minhang, a suburban district in Shanghai’s southeast.

Future Technology: Working on the intelligent and connected vehicle.

On-Site Testing: Engineers validating control unit software on HiL test rigs.

A regular part of the Shanghai branch’s operations is its cooperation with renowned Tongji University. Every two years, the partners jointly host the Tongji Porsche Engineering Symposium, a platform for top execs to discuss the latest developments in the automotive trade. The cooperation also includes exchanges in the form of internships and thesis programs as well as sponsoring the local Formula Student team, in which students design their own race cars and take part in competitive racing. This provides the branch with ideal connections to one of China’s best talent pools—essential for continued growth in one of the world’s most important automotive markets.

“China is setting out on a new path of its own”

Kurt Schwaiger

The branch manager has lived in Shanghai for the past ten years. The branch first made a name for itself with chassis design. Today, its portfolio covers a wide range of fields.

Three Questions for Kurt Schwaiger

What do customers in China expect?

A rapid response, most of all. Everything here moves much faster. That’s why it’s so important to have our branch in Shanghai, in the same time zone as our customers and with the requisite language skills, so that we can react quickly and flexibly to requirements. There’s also a keen eye to prices.

Is it difficult to find good staff in China?

Generally speaking, China has an abundance of good, skilled workers. But locating them isn’t always so easy. Here in Shanghai, our location gives us an edge because a lot of Chinese people want to be here. Our good connections to Tongji University also help us find new junior talent. And there’s our strong brand, of course. All this keeps employee turnaround in the low single-digit figures.

How does the Chinese automotive market differ from its western counterpart?

Today, Chinese businesses are at a really high level. Highly automated driving is going to be a major thing in China in the years to come. Here, China is treading new paths, as a pioneer. For V2X applications, for instance, they’ll be using only mobile comms standards like LTE-V and 5G. Because the Chinese government doesn’t permit the export of geo-based data, all the testing needs to be done here in the country.

In Brief

The Chinese market is heavily in flux. Customers expect the best technology and solutions tailored to their requirements—for example when it comes to integrating vehicle and smartphone. In its branch in Anting, Porsche Engineering is right on the market’s pulse and responds rapidly to local customers’ queries. At the same time, the staff supply western businesses with valuable insights into the Chinese market.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2020.

Text: Thomas Kern

Contributor: Kurt Schwaiger

Photos: Kai Hartmann

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de

Consumption Data

911 Carrera Cabriolet

Fuel consumption (urban): 12.9 l/100 km

Fuel consumption (highway): 7.6 l/100 km

Fuel consumption (combined): 9.6 l/100 km

CO₂ emissions (combined): 218 g/km

Efficiency class: G

Taycan Turbo S

Electricity consumption (combined): 26.9 kWh/100 km

CO₂ emissions (combined): 0 g/km

Efficiency class: Germany: A+ Switzerland: B