Smarter Testing with the ComBox App

Evaluation at the Touch of a Button

The ComBox app from Porsche Engineering records relevant measurements in test vehicles, evaluates them with the help of AI—on the spot in some cases—and automatically sends the results and measurement data to the cloud. This reduces the manual workload for test drivers and increases the efficiency when developing and validating new vehicle functions.

Drivers of development vehicles already have their hands full identifying, documenting and reporting technical abnormalities of new vehicle functions to the respective development departments during their test drives. “We welcome any simplification of our work, especially with regard to ADAS and drive issues, the validation of which is particularly time-consuming,” reports Jan Wörner, Project Manager in Data Driven Testing & Vehicle Functions at Porsche Engineering. “That’s exactly why we developed the ComBox app: It’s the engineer’s companion and serves as a kind of digital assistant during the testing. It also performs many calculations directly in the vehicle and identifies important scenarios in the measurement data without the driver having to intervene. This edge computing means we have to send significantly less data to the cloud for evaluation.”

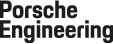

Versatile: The ComBox app provides users with six modes that make their work much easier. They can be easily selected upon launching the app.

Standard/Single Service: A single press of the button is all it takes to trigger a measurement. All vehicle data in a time frame of six minutes is loaded into the cloud—for example, from three minutes before to three minutes after triggering.

Six Modes to Choose From

A commercially available high-end smartphone serves as the platform for the ComBox app. Most of the computing resources of this smartphone are available to the assistance software developed by Porsche Engineering. After launching the app, the user can select from six different modes: “Standard / Single” can be used to trigger measurement of vehicle control unit data at any time in order to record this measurement data and upload it to the cloud. “Scene Recognition” mode can record general traffic scenarios that are relevant for ADAS functions, for example. “Acoustic Detection” mode uses AI help to find distracting noises, while “Infotainment Recording” offers support with correcting display problems. “These four modes have one thing in common: After a manual or automatic trigger, they record patterns or errors and send the corresponding data to the cloud,” says Wörner. “Shift report” mode is used after the test drives and reduces the work involved in creating the log. “All modes reduce the manual workload, which increases efficiency and cuts human errors in the testing and fault elimination process,” explains Wörner.

Access to the Vehicle Buses

The prerequisite for this is that all modes have access to the relevant vehicle buses and data. The ComBox app obtains this data from a data logger in the test vehicle, such as Porsche Engineering’s Car Data Box. “The data logger has full access to all bus systems such as CAN, LIN, FlexRay, and Automotive Ethernet, which it uses to provide information about the current status of all vehicle systems,” explains Wörner. “It forwards this data to the smartphone with the ComBox app–either via cable using an Ethernet-to-USB adapter or via WiFi, if there is a wireless access point in the vehicle that is connected to the data logger.”

With the ComBox app’s Standard/Single service, the driver can trigger a measurement manually if any abnormality occurs. “This means that all measurement data from the vehicle is recorded within a defined timeframe around the trigger time and loaded into the cloud. The timeframe could be, for example, from three minutes before the trigger time to three minutes after it,” says Wörner. “The driver can also input a voice explanation into the smartphone, which is then automatically converted into text and sent to the cloud together with the measured data via a 5G network. With this method, detailed additional information can be recorded immediately and thereby be made available without delay for the downstream error analysis. The other modes also offer this option.“

“The ComBox app serves as a reliable assistant for testing and, at the same time, functions as a central data interface.”

Jan Wörner

Project Manager in Data Driven Testing & Vehicle Functions at Porsche Engineering

“Acoustic Detection” mode automatically identifies certain unwanted noises in the vehicle and, under certain framework conditions, provides support with identifying the cause. “The ComBox app uses the smartphone’s high-quality microphone to detect the background noise. This makes reliable detection possible that is as cost-effective as it is space-saving—and without any additional equipment. However, those who wish to can still connect special microphone technology,” Wörner explains. “Artificial intelligence is used to analyze the audio recording directly in the vehicle: We use a neural network that we have trained with noise interference patterns.” If the ComBox app detects an unwanted pattern, it automatically generates a message to this effect and loads it into the cloud together with the relevant audio file. Other measurements such as the current speed of the vehicle, the gear engaged, and the engine speed are also transmitted. This extensive automation significantly reduces the workload required.

For example, ”Acoustic Detection“ mode can automatically detect the signature howling noise of turbochargers, as well as certain intrusive wind noises. The list of automatically identifiable noise types will be expanded to include further noise categories in the future. In addition, the neural network has also learned how normal driving sounds as a reference. Using the ComBox app can significantly reduce the effort involved in detecting and analyzing acoustic issues. “In the past, there was often no suitable measuring equipment in the vehicle when such anomalies occurred,” reports Wörner. “We therefore first had to equip a vehicle with the measuring technology and then deliberately recreate the fault. This was very time-consuming and associated with high costs.”

Traffic Signs Correctly Detected: Green areas indicate that the results of the vehicle and the ComBox app match.

Traffic Signs Incorrectly Detected: If the results do not match, the color changes to red. The measurements are also transferred to the cloud.

Abnormalities in the infotainment system can also be logged using the ComBox app. This is where “Infotainment Recording” mode comes in. This mode records the content of the screens (driver, central, and passenger display) while the vehicle is moving. “If the test driver notices a problem, a simple press of a button in the app will suffice to automatically upload a short video to the cloud. The video also contains the screen content from a few seconds before the function was triggered,” says Wörner. “Abnormalities such as misaligned text, an incorrectly placed icon in the navigation system or the wrong element being overlaid usually only appear for a few seconds, which is why we were often unable to record them in time in the past. ‘Infotainment Recording’ mode gives us a lot more room to identify and flag such issues.”

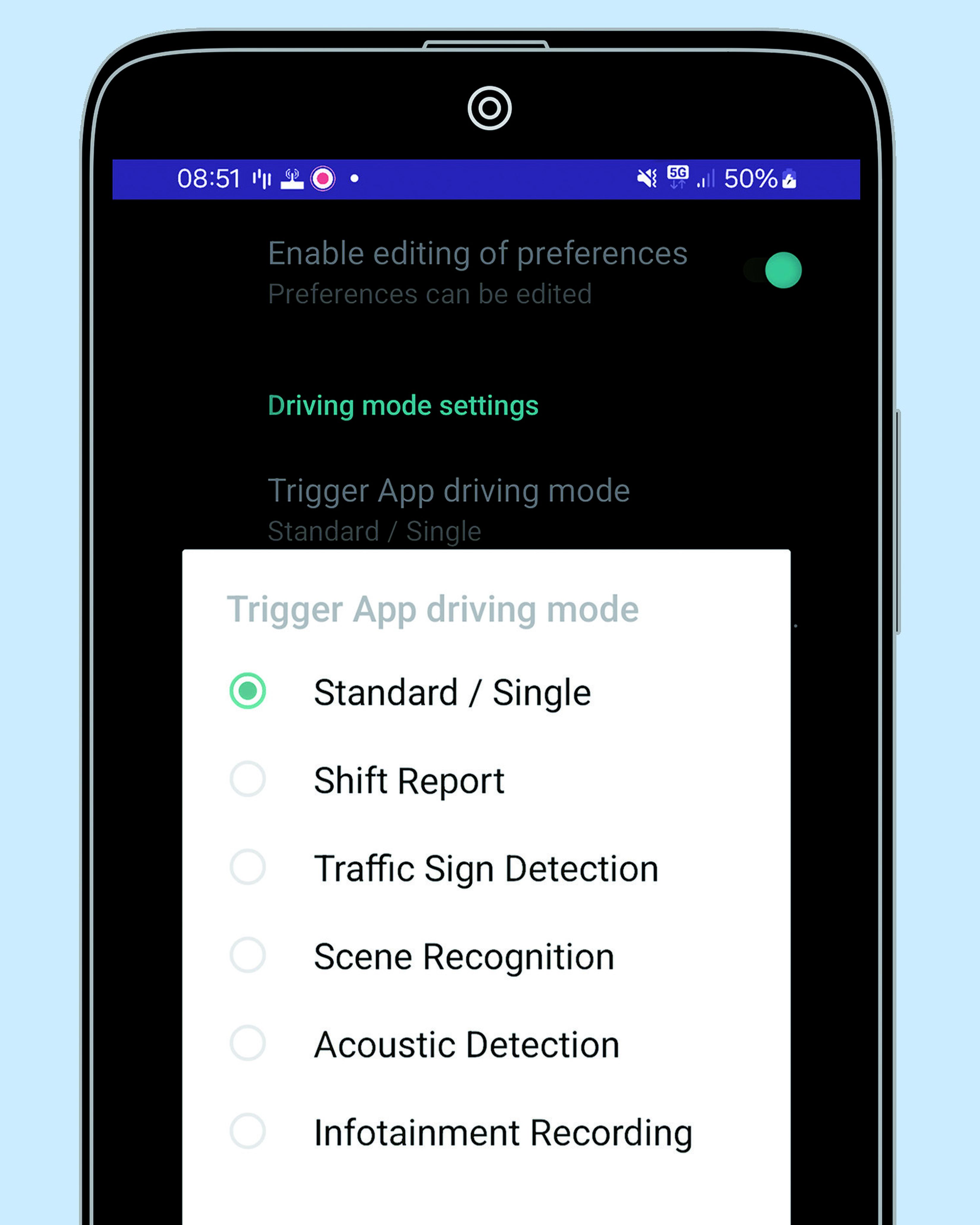

Between the Measurement Technology and the Cloud: The ComBox App Is the Digital Assistant for Test Drives

The ComBox app has access to the vehicle buses via a data logger. Its six modes use this data to detect anomalies, for example. These anomalies are transferred to the cloud together with the associated measurements and can also be commented on via speech-to-text. Conversely, the measuring technology can also be configured in the test vehicle via the ComBox app.

Automatic Scene Recognition

“Scene Recognition” mode is still under development. It aims to automatically detect typical traffic scenarios that are relevant for testing a new ADAS function, such as being cut off by a vehicle in front—an incident that the ACC function, for example, may need to counter by braking. Such scenarios are described by the signals that occur in the vehicle and the order they occur in. These signals include the current speed, the brake pressure, and the distance to the road user in front. Edge computing directly within the app allows even complex scenarios and test cycles to be detected intelligently and automatically, without the driver having to intervene.

“We can send a specific scenario pattern – containing the sequence of events and the combination of signals—from the cloud to all vehicles equipped with the ComBox app,” says Wörner. “As soon as the pattern you are looking for appears somewhere, the ComBox app sends the current measurement data to the cloud. This allows developers to see whether the new vehicle function has responded as desired.” The big advantage here is that, in the future, all vehicles in a test fleet that are running the ComBox app can be used to search for the relevant patterns—and not just those vehicles that are, for example, specifically on the road for ADAS testing purposes. “This saves a lot of time,” says Wörner, “because we no longer have to carry out certain dedicated test drives separately. They are done by other vehicles along the way, so to speak.”

Automatic Test Reports: The ComBox app supports report creation during and after the test drive. Pressing the microphone button suffices to enter comments via speech-to-text. It is also possible to take photos or videos and to display a list of all issues.

Filling Out a Report: Pressing the chequered flag button leads to a list of all issues; the list can be supplemented with comments and photos.

Evaluation Complete: At the end, the ComBox app displays an overview of all recorded issues and enables the report to be sent using the “SUBMIT” button.

“Shift report” mode greatly facilitates the documentation of test drivers and measurement results. For quality assurance purposes, new vehicles undergo extensive endurance tests that include many repetitions—for example, opening the luggage compartment and sliding the sunroof several times or repeatedly charging the battery. This mode uses vehicle measurement signals to partially fill out the reports automatically—with data such as the number of repetitions performed. The reports need only to be checked after the journey and corrected if necessary. What’s more, the driver can record all errors that occur while driving directly in the ComBox app and add photos if necessary. “After each journey, the driver fills out a report and indicates how often they have carried out which action,” explains Wörner. “Completing these reports manually means a great deal of work and, as with any manual activity, errors can creep in. This is where the app effectively remedies the problem and we can increase the quality of the reports.”

The six modes of the ComBox app have already proved themselves in practice and are constantly being enhanced. “The ComBox app thus serves as a reliable assistant for testing and, at the same time, functions as a central data interface,” Wörner sums up. “Another advantage is its ability to be used seamlessly and comprehensively for more or less all vehicle derivatives.” In the future, Porsche Engineering plans to offer this tool, including the backend in the cloud, to its industrial customers as a self-contained product. The app’s different modes can be added on individually depending on customer requirements.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2025.

Text: Christian Buck

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de