Porsche Engineering Brings Macan Power to the 850 Fantom Air

Electric Power to the Water

From an SUV to an eBoat: Porsche AG, Porsche Engineering, Studio F. A. Porsche, and boat-building company Frauscher have jointly developed the 850 Fantom Air—a sports boat with an electric powertrain that is based on standard components of the Porsche Macan Turbo. The project shows how Porsche Engineering is transferring automotive expertise to other sectors in order to establish innovative powertrain systems there as well.

Michael Frauscher “hooks up”. That’s the phrase among motorboat skippers for when you’re at full throttle. The bow rises out of the water, and the boat accelerates to its maximum speed of more than 85 km/h within a few seconds. The powertrain is not only powerful, but also barely audible. Frauscher, co-owner and Managing Director of the Austrian boatyard of the same name, is more than satisfied with the result of the maiden voyage on the local lake, Traunsee. It took less than a year for the development team from Porsche Engineering, Porsche AG, and Frauscher to jointly develop the 850 Fantom Air from the design stage to the first prototype. Porsche AG took the lead in the project, and Philip Ruckert was appointed eBoat Project Manager by the Executive Board of Porsche AG. The technical foundation was laid together with Porsche Engineering. A short time later, the decision was made to integrate the project into the Macan model series and bring it to series production. Porsche Engineering was responsible for the technical implementation of the project content. “Only through close and trust-based cooperation with the individual specialist departments of Porsche AG have we succeeded, in just two years, in implementing a development that is ready for series production,” explains Thomas Warbeck, Specialist Project Manager at Porsche Engineering.

Powerful Yet Quiet: The electric powertrain of the 850 Fantom Air brings the boat up to maximum speed in just a few seconds—thanks to components from the electric vehicle sector. The throttle also borrows from Porsche sports cars by offering the familiar Sport and Sport+ driving mode buttons.

The special feature of the 850 Fantom Air is hidden in the hull: Instead of the usual petrol or diesel engine, this boat has a powerful electric powertrain. As in an all-electric vehicle, the powertrain delivers high torque from a standstill and at the same time makes the boat extremely quiet. The main components of the 800-volt powertrain—including the battery and drive module—originate from the rear-axle drive of the Macan Turbo. The passenger car components have been specifically adapted for marine use, as each sector has individual requirements that must be met by specific solutions. “In the automotive sector, we have built up in-depth know-how in technologically state-of-the-art developments. We use this as a basis to analyze the requirements for the vehicle and compare them with the specifications for the new target application. This shows us the changes needed to the system integration for both components and software, and we implement these changes on the development side,” says Warbeck. Differences between use on the road and on the water can be seen, for example, in the driving profiles: While dynamic load requirements are the main focus of the car, the boat tends to have high continuous loads. As a result, this means that high-performance cooling must be provided. This was achieved on the 850 Fantom Air by means of optimized pump actuation. When building a boat, the limited space in the hull must also be taken into account when it comes to the powertrain and the battery. Additionally, there are specific requirements for vibration resistance and media compatibility due to the fact that the system can come into contact with salt water, for example. What’s more, the E/E architecture of the 850 Fantom Air has been reduced to the most necessary components and supplemented by a specially developed control module.

“Only through close and trust-based cooperation with the individual specialist departments of Porsche AG have we succeeded, in just two years, in implementing a development that is ready for series production.”

Thomas Warbeck

Specialist Project Manager at Porsche Engineering

“Look and Feel” of a Porsche

In the development project, Porsche Engineering was responsible, among other things, for requirements management, mechanical design, electrical system and ECU development, as well as testing. Moreover, there was a close cooperation with Studio F. A. Porsche, Porsche AG, and Frauscher when it came to component selection and design. “Our aim was to bring a typical Porsche ‘look and feel’ on board so that Porsche drivers would feel right at home on the boat. For example, we developed a throttle with the familiar Sport and Sport + driving mode buttons, car-like display graphics, and a boat steering wheel in a Porsche look,” reports Project Manager Ruckert.

Quietly Crossing Lake Garda: Jörg Kerner, Vice President Product Line Macan at Porsche AG, was most surprised by the boat’s pleasant soundscape. The Porsche-quality leather armchairs were also impressive.

The permanently excited synchronous electric motor (PSM) installed on the rear axle of the Macan Turbo impresses with its high efficiency and power density. In the 850 Fantom Air, it delivers up to 400 kW. The electrical components of the car engine, such as the stator and rotor, were adopted for the boat project unchanged. However, the motor housing has been newly developed. In cars, a gearbox is integrated into the motor casing to reduce the high engine speeds. In the boat, in contrast, the motor runs at a significantly lower speed of 6,000 rpm instead of the more than 16,000 rpm in a vehicle, which is why internal reduction was not required. “We have developed and tested the new housing specifically to marine standards in terms of material selection and pairings, for example by means of adapted tests for salt spray, corrosion, and leaks,” explains Sebastian Riesbeck, Specialist Project Engineer at Porsche Engineering. The only gearbox in the powertrain is the standard boat Z-drive in front of the propeller, which reduces the speed to around 3,000 rpm. "The necessary adjustments included the actuation for the marine powertrain, meaning that we could produce a combustion engine-like behavior with the advantages of an electric drive, in particular when it came to the torque characteristics,” says Riesbeck. The connection between the motor and the Z-drive was a challenge. A slip clutch was used in the first prototypes, however, it could not withstand the high engine torques of up to 700 Nm and high torque gradients. The current configuration consists of a robust jaw coupling with elastomer insert. In addition, the torque curve of the motor was adapted to the load limits of the clutch, allowing a long-lasting solution for series use to be presented.

“We have transferred our quality expectations from the road to the water without compromise.”

Philip Ruckert

eBoat Project Manager for Porsche AG

The electric powertrain draws its energy from a lithium-ion battery with a capacity of 100 kWh. The wave impacts on the water cause the boat to vibrate, which can be transmitted to the battery and result in damage. “In order to quantify the problem and derive suitable technical countermeasures, we carried out reference measurements in the car and compared them with the values in the boat,” says Warbeck. The boat now uses a load-bearing mounting frame with steel cable damping for the battery to cushion harmful excitations. “With the low central positioning of the powertrain and the batteries in the hull, we have achieved unique handling characteristics. What’s more, there is a pleasant soundscape on the boat. That surprised me the most,” says Jörg Kerner, Vice President Product Line Macan at Porsche AG.

Adapted Cable Harness

The electric cables also had to be adapted to the conditions on the water and to marine standards: The low-voltage cable harness has been almost fully reconfigured to meet the specifications regarding cable cross-sections and protective sheathing. The changes to the high-voltage wiring harness compared to the car relate to extended charging cables with a modified charging socket. In addition, all components had to be certified for use in the marine sector.

One obstacle to the integration of electric drives into motorboats is the often high level of intricacy involved in integrating the individual components into the boat’s hull. The development team therefore implemented a modular concept that consists of a drive unit with cooling, control modules, and other subsystems, as well as the battery unit with the support frame. Both modules can be mounted directly in the hull in the boatyard using defined mounting points. “This modularization represents a solution that is unique worldwide, being one that leads to lower development costs for the manufacturer of the boat and considerably simplifies the installation of the drive in the boatyard,” says Riesbeck.

Partners: Michael Frauscher and Jörg Kerner examine sketches of the eBoat. The lithium-ion battery adopted from the Macan is located under the sun deck in the rear.

In the Macan Turbo, the control module architecture of the drive is aligned with the data connections and communication protocols of the vehicle. Porsche Engineering has developed a special gateway control module to bring the worlds of cars and boats together on board. “Here, too, we have taken into account the special marine requirements, such as those of EN 55016-2-3 and EN 6094, for example with regard to electromagnetic compatibility (EMC), compass deviation or bus disturbances due to overvoltage,” says Dietmar Luz, Electrical/Electronics Senior Expert at Porsche Engineering. The gateway control module is where devices such as the throttle and the marine-specific displays are connected, but above all it forms the interface to the electronics of the individual drive components.

Using what is called a rest-bus simulation, the control module supplies the components with information and signals, for example, that come from the ESP brake system in the car, something that is not needed in the boat. “Because you can’t record wheel speeds on the water, or because you don’t have a parking brake, for example, there were many empty interfaces. To continue with this example, the Macan only charges when the parking brake is applied. We had to find a way to generate that and other missing signals,” Kerner explains. “We were able to draw on our extensive expertise in the development and validation of sophisticated electronic architectures to analyze the signal flows in the car and to set up a suitable rest-bus simulation. It was also only possible to implement this through our detailed technical knowledge of the Porsche components and with the support of those responsible for the components at Porsche,” reports Luz.

≤

400

kW

100

kWh

When implementing the software of the gateway control module based on AUTOSAR, the team of Porsche Engineering experts from Germany, Romania and the Czech Republic entered uncharted territory, as there were no standards for linking the boat-side bus system with the powertrain from the car. The close cooperation between the sites allowed the challenging development task to be implemented in a short time despite the small team. It was possible to transfer the high requirements of functional safety and software quality from the automotive sector to the motorboat sector.

Award-Winning Project

“A success story needs fascinating products. The Porsche name has always stood for performance, quality, and design. We have kept this promise with our eBoat project, too,” as Kerner sums up the success of the project. Ruckert adds: “We have put the boat through its paces and transferred our quality expectations from the road to the water without compromise. This is only possible if everyone involved is passionate about the project.” The series-production model of the 850 Fantom Air was crowned “Powerboat of the Year 2024” prize at the Boat Düsseldorf trade fair in 2024 and was named “Best Boat of 2024” in the eBoat category at the “Boat & Fun” trade fair in Berlin. The boat manufacturer Frauscher is wholly satisfied with the result of the joint project.” “Due to the high level of interest from customers, we have now started to manufacture a small series of 25 boats,” says Florian Helmberger, Director Sales & Marketing at Frauscher. “The first boats in the limited edition have already been delivered and are making customers around the world happy.” However, the powertrain developed by Porsche Engineering can also be easily integrated into other boats of different sizes and classes. For larger boats of more than ten meters in length, a drive with several parallel powertrains is even conceivable. “Our proven development methodology for transferring technology from cars to other sectors is universally applicable and can be used in many other areas such as the construction machinery sector,” says Warbeck.

“The first boats in the limited edition have already been delivered and are making customers around the world happy.”

Florian Helmberger

Director Sales & Marketing at Frauscher

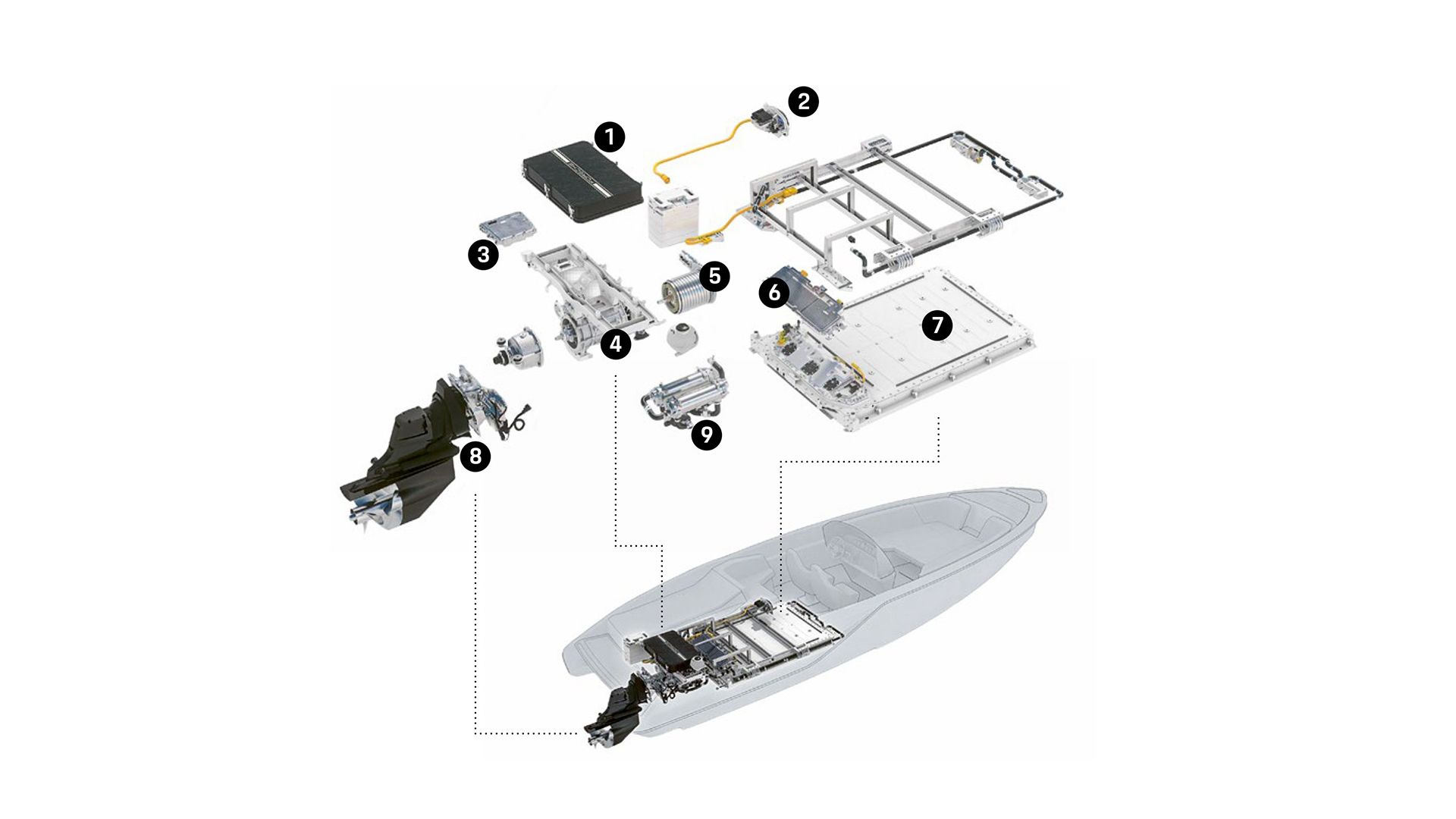

High Voltage, High Power

Equipped with the drive technology of the all-electric Porsche Macan, the electric sports boat offers outstanding handling characteristics.

1 The control unit contains all the control modules of the drive.

2 The fast-charging connection guarantees short charging times.

3 The inverter supplies the motor with the electrical power it needs at any given moment.

4 The motor housing has been specially developed and tested to marine standards.

5 The synchronous electric motor boasts impressively high efficiency and power density.

6 The integrated Power Box uses a CCS2 socket for charging with AC and DC voltage.

7 The high-voltage battery is mounted directly in the hull using a support frame.

8 The Z-drive transfers the power of the electric motor to the propeller in the water.

9 The heat exchanger prevents excessive temperatures in the battery, inverter and electric motor.

Summary

Porsche Engineering, Porsche AG, and the Austrian boat manufacturer Frauscher have jointly developed the 850 Fantom Air. The eBoat has a powertrain that essentially uses standard components of the Porsche Macan. They have been adapted to the requirements of the marine sector.

Info

Text first published in the Porsche Engineering Magazine, issue 1/2025.

Text: Richard Backhaus

Copyright: All images, videos, and audio files published in this article are subject to copyright. Reproduction in whole or in part is not permitted without the written consent of Porsche Engineering. Please contact us for further information.

Contact

You have questions or want to learn more? Get in touch with us: info@porsche-engineering.de

Consumption Data

850 Fantom Air Battery

Capacity (gross): 100 kWh DC

Charging capacity: > 250 kW AC

Charging capacity: 11 kW

Charging time: Under ideal conditions, SoC (state of charge) from 10 to 80 percent in well below 30 minutes

CE category: C

Continuous/peak power of electric motor: 170/400 kW

Range at cruising speed: 45 km

Macan Turbo

Power consumption (combined): 20.7318.9 kWh/100 km

CO2 emissions (combined): 0 g/km

CO2 class: A